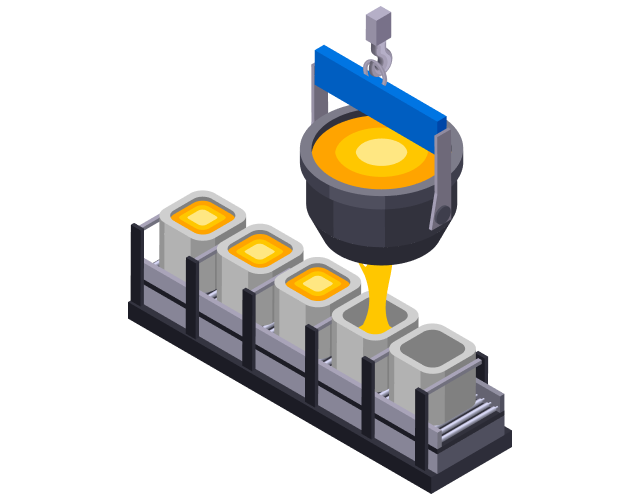

A Deep Study the Different Sorts Of Metal Casting and Their Utilizes

Metal Casting incorporates numerous strategies, each customized for certain applications and needs. From the cost-efficient sand spreading method to the precision of investment casting, each process has one-of-a-kind advantages. Pass away casting attracts attention in high-volume production scenarios, while shed foam casting presents innovative layout possibilities. In addition, long-term mold and mildew casting is recognized for its resilience. Understanding these techniques opens up a window right into their functional uses and effects in different markets. What exists underneath the surface of these casting strategies?

Sand Spreading: A Cost-efficient and versatile Approach

Although various casting approaches exist, sand spreading continues to be one of the most cost-efficient and flexible strategies in the metalworking sector. This technique employs a blend of sand and a binding agent to develop molds, enabling the manufacturing of parts in diverse shapes and sizes. Sand casting is specifically beneficial for small to medium manufacturing runs, as it needs marginal upfront investment in tooling compared to various other casting techniques.

The procedure begins with the creation of a mold, where molten steel is gathered to create the desired item once cooled down. Its flexibility enables using numerous metals, consisting of aluminum, steel, and iron. Additionally, sand casting can fit complex geometries, making it suitable for a series of applications, from auto parts to elaborate artistic items. Overall, sand casting's effectiveness and flexibility strengthen its significance in the production landscape.

Financial Investment Spreading: Accuracy and Information for Complex Shapes

Investment spreading stands out as a method renowned for its capability to create extremely outlined and detailed elements. This process involves producing a wax pattern that is coated with a ceramic shell, which is after that heated up to remove the wax and harden the covering. The result is a specific mold that can capture complex geometric shapes with amazing precision.

This casting technique is specifically advantageous for producing get rid of thin walls, great attributes, and tight tolerances, making it optimal for markets such as aerospace, automobile, and clinical gadgets. Financial investment spreading accommodates a range of metals, consisting of stainless steel, light weight aluminum, and titanium, making it possible for producers to satisfy details material demands.

The procedure decreases machining requirements post-casting, which can boost efficiency and lower manufacturing prices. In general, financial investment casting is a favored choice for applications where precision and information are vital.

Pass Away Spreading: High-Volume Manufacturing With Excellent Surface Area Finish

Pass away spreading is a highly efficient manufacturing procedure that masters producing large quantities of steel parts with exceptional surface area finishes. This approach involves requiring molten metal into a mold dental caries under high pressure, enabling fast production cycles and harmony in the ended up items. Frequently utilized materials include zinc, magnesium, and aluminum, which provide superb mechanical residential properties and deterioration resistance.

Die casting is specifically valuable for markets such as automobile, electronics, and durable goods, where accuracy and quality are critical. The process enables detailed styles, minimizing the requirement for added machining and ending up procedures. Additionally, the smooth surfaces developed via die spreading commonly require minimal post-processing, causing reduced general manufacturing expenses. As a high-volume manufacturing technique, die casting is suitable for suppliers seeking effectiveness without jeopardizing on quality, making it a recommended selection for numerous applications throughout various sectors.

Lost Foam Casting: Innovative Strategy for Intricate Styles

Lost foam spreading transforms the production of complex steel parts by making use of a distinct procedure that removes the requirement for traditional molds. Instead of traditional mold-making, this approach utilizes a foam pattern that is coated with visite site a refractory product. Once the pattern is set, liquified metal is poured straight into the mold, causing the foam to leave and evaporate behind an accurate tooth cavity for the steel to load. This innovative method permits detailed designs and in-depth functions that may be testing to achieve with various other casting approaches.

Furthermore, lost foam spreading can lower waste and power consumption, making it an eco-friendly choice. Industries such as aerospace and vehicle advantage considerably from this method, as it sustains the creation of lightweight parts with complicated geometries. In general, shed foam casting attracts attention for its capacity to deliver high-quality, personalized metal components effectively.

Irreversible Mold And Mildew Spreading: Resilience and Uniformity in Steel Parts

Long-term mold and mildew spreading is an extremely reliable method for creating consistent and durable steel components, leveraging multiple-use molds that are normally made from steels such as iron or steel. This spreading procedure entails putting molten metal right into these molds, which are preheated to boost product high quality and reduce problems. Making use of multiple-use mold and mildews not just reduces waste however also permits higher manufacturing rates, making it economically advantageous for manufacturers.

The resulting components show superb dimensional accuracy and surface area coating, making them perfect for applications in auto, aerospace, and industrial equipment. Furthermore, long-term mold and mildew spreading can accommodate a range of alloys, better expanding its versatility. The longevity of the actors parts is improved due to the regulated air conditioning rates that promote better grain structures. Overall, this casting strategy sticks out for its capacity to create high-grade metal parts that meet rigorous performance requirements, making sure dependability in requiring settings.

Frequently Asked Concerns

What Products Can Be Used in Various Steel Casting Procedures?

Numerous products can be used in Metal Casting processes, consisting of light weight aluminum, zinc, bronze, and iron. Each material offers one-of-a-kind residential or commercial properties, affecting the spreading approach's performance, strength, and viability for different applications in manufacturing.

Exactly How Do Casting Methods Influence the Mechanical Characteristics of Metals?

Casting methods considerably influence the mechanical buildings of steels, impacting variables like ductility, solidity, and toughness. Variants in cooling down prices and mold products can result in different microstructures, inevitably impacting the efficiency of the last product.

What Are the Ecological Effects of Steel Casting Procedures?

Metal Casting procedures can bring about air and water contamination, resource deficiency, and substantial power consumption (Aluminum Foundry). Additionally, the generation of waste products and greenhouse gas emissions greatly affects the setting and contributes to climate adjustment

Exactly how Do You Choose the Right Spreading Method for a Task?

Choosing the right spreading technique entails reviewing job needs, product residential properties, intricacy, and manufacturing quantity. Variables like cost performance, coating top quality, click to find out more and preparation also play vital functions in establishing the most ideal approach.

What Safety and security Safety Measures Should Be Taken During Metal Casting Operations?

During Metal Casting procedures, security precautions include using protective equipment, making certain proper air flow, carrying out equipment inspections, maintaining a tidy workspace, and having emergency methods in location to handle potential risks like burns or harmful fumes.

From the cost-effective sand casting technique to the precision of financial investment casting, each procedure has unique benefits. Die spreading is an extremely effective production process that stands out in creating huge volumes of steel components with phenomenal surface coatings. Lost foam casting transforms the manufacturing of intricate metal parts by using an unique procedure that removes the requirement for traditional molds (Aluminum Foundry). Permanent mold casting is a highly reliable look at more info technique for creating long lasting and regular steel components, leveraging multiple-use mold and mildews that are generally made from steels such as iron or steel. Various materials can be made use of in Metal Casting procedures, including light weight aluminum, bronze, iron, and zinc